Lub tsev

Cov lus qhia

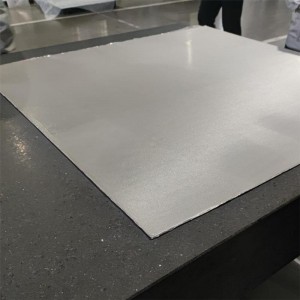

Ntaub ntawv

DIN 1.4404 / AISI 316L, DIN 1.4539 / AISI 904L

Monel, Inconel, Duple Steel, Hastelloy alloys

Lwm cov ntaub ntawv muaj nyob rau ntawm kev thov.

Lim Khawm: 1 -100 microns

| Descriptsion | Lim Khawm | Lub tsev | Qhov tuab | Porosity | Huab cua permeability | Rp | Qho hnyav | Cov tawv nqaij npuas |

| μm | mm | % | (L / min / cm²) | N / cm | kg / ㎡ | (mmh₂o) | ||

| SSM-F-1 | 1 | 100 + 400x2800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 1.82 | 1080 | 8.4 | 360-600 |

| SSM-F-2 | 2 | 100 + 325x2300 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.36 | 1080 | 8.4 | 300-590 |

| SSM-F-5 | 5 | 100 + 200x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.42 | 1080 | 8.4 | 260-550 |

| SSM-F-10 | 10 | 100 + 165x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.08 | 1080 | 8.4 | 220-500 |

| SSM-F-15 | 15 | 100 + 165 x1200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.41 | 1080 | 8.4 | 200-480 |

| SSM-F-20 | 20 | 100 + 165 x800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 4.05 | 1080 | 8.4 | 170-450 |

| SSM-F-25 | 25 | 100 + 165x600 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.12 | 1080 | 8.4 | 150-410 |

| SSM-F-30 | 30 | 100 + 400 + + 100 + 64 + 64/12 | 1.7 | 37 | 6.7 | 1080 | 8.4 | 120-390 |

| SSM-F-40 | 40 | 100 + 325 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.86 | 1080 | 8.4 | 100-350 |

| SSM-F-50 | 50 | 100 + 250 + 100 + 64 + 64/12 | 1.7 | 37 | 8.41 | 1080 | 8.4 | 90-300 |

| SSM-F-75 | 75 | 100 + 200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 8.7 | 1080 | 8.4 | 80-250 |

| SSM-F-100 | 100 | 100 + 150 + 100 + 12/64 + 64/12 | 1.7 | 37 | 9.1 | 1080 | 8.4 | 70-190 |

Qhov loj

500 hli1000mm, 1000mmx1000mm

600mmx1200mm, 1200mmx1200mm

1200mmx1500mm, 1500mmX2000mm

Daim ntawv thov

Laib cov txaj, cov txiv ntoo txiv ntoo, centrifuges, mob ntawm silos, kev siv hauv biotechnology.

Tsab ntawv

LCL txhais tau tias tsawg dua ib lub thawv ntim

FCL txhais tau tias tag nrho cov thawv ntim khoom

Tsib Txheej Txheej Txheem Mesh feem ntau yog siv rau kev ua kom huv thiab siv hluav taws xob, kev hloov pauv ntawm huab cua thiab loj hloov pauv, cov suab nrov txo qis, txaus ntshai, thiab lwm yam.

Lub tsib-txheej sintered mesh muaj kev cuam tshuam nrog kev sib txuas lus ntawm cov khoom siv lim uas yog cov khoom siv uas ua rau lub siab tawv nqaij hauv av lossis kua. Nws tuaj yeem raug siv los lim cov pa luam yeeb thiab hmoov av nyob rau hauv cov pa roj kub-kub. Nws tuaj yeem tiv taus ntau qhov kub thiab txias txog li 600 ° C. Nws muaj lub zog siab thiab yog ib qho yooj yim rau cov duab.

1. Kev ua kom meej meej ntawm ntau cov roj roj nplua hydraulic hauv kev lag luam Machinery;

2

3. Daim ntawv thov ntawm roj homogenization hauv cov hmoov kev lag luam, phaj ntim hauv cov hlau lag luam;

4. Cov neeg faib tawm hauv cov khoom siv hluav taws xob, thiab lwm yam.