Lub tsev

Ntaub ntawv

DIN 1.4404 / AISI 316L, DIN 1.4539 / AISI 904L

Monel, Inconel, Duple Steel, Hastelloy alloys

Lwm cov ntaub ntawv muaj nyob rau ntawm kev thov.

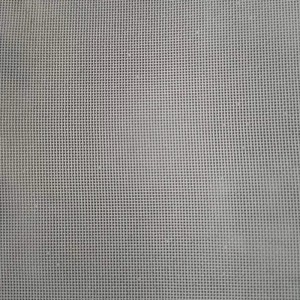

Lim Khawm: 1 -200 microns

Cov lus qhia

| Kev qhia tshwj xeeb - xuas nrig ntaus phaj sintered hlau mesh | ||||

| Kev piav txog | Lim Khawm | Lub tsev | Qhov tuab | Porosity |

| μm | mm | % | ||

| SSM-P-1.5T | 2-100 | 60 + filtric txheej + 60 + 30 + φ4x5px1.0t | 1.5 | 57 |

| SSM-P-2.0t | 2-100 | 30 + lim txheej + 30 + φ5x7px1.5t | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60 + filtric txheej + 60 + 30 + φ4x5px1.5t | 2.5 | 35 |

| SSM-P-3.0t | 2-200 | 60 + filtric txheej + 60 + 20 + φ6x8px2.0t | 3 | 35 |

| SSM-P-4.0t | 2-200 | 30 + lim txheej + 30 + 20 + φ8x10px2.5t | 4 | 50 |

| SSM-P-5.0t | 2-200 | 30 + lim txheej + 30 + 20 + 20 + 10 + φ8x10px3.0t | 5 | 55 |

| SSM-P-6.0t | 2-250 | 30 + lim txheej + 30 + 20 + 20 + 10 + φ8x10px4.0t | 6 | 50 |

| SSM-P-7.0t | 2-250 | 30 + lim txheej + 30 + 20 + 20 + 10 + φ8x10px5.0t | 7 | 50 |

| SSM-P-8.0t | 2-250 | 30 + lim txheej + 30 + 20 + 20 + 10 + φ8x10px6.0t | 8 | 50 |

| Lub thickness ntawm lub punching phaj thiab cov qauv ntawm cov mesh xees tuaj yeem kho tau raws li tus neeg siv yuav tsum tau ua. | ||||

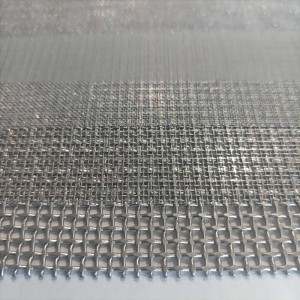

Cov lus hais, yog tias nws yog siv rau hauv lub tshuab lim lim lim dej ntau heev, lub tshuab lim phaj yuav ua tau tsib txheej thiab xuas nrig ntaus phaj sintered ua ke.

Ntawd yog 100 + lim txheej + 100 + 12/64 + 64/12 + 4.0t (lossis ntawm lwm lub phaj tuab punching phaj)

Lub thickness ntawm punching phaj tseem yog nyob ntawm koj lub siab xav tau.

Cov khoom no yog qhov zoo rau cov kev thov kom siab dua qub ntawm cov tshuaj thiab kev lag luam backering thiab kev lag luam online, muaj zog ntau yam.

Cov Ntawv Thov

Kev kho zaub mov & dej haus, dej kho, dej tshem tawm, chaw muag tshuaj, tshuaj lom neeg, thiab lwm yam.

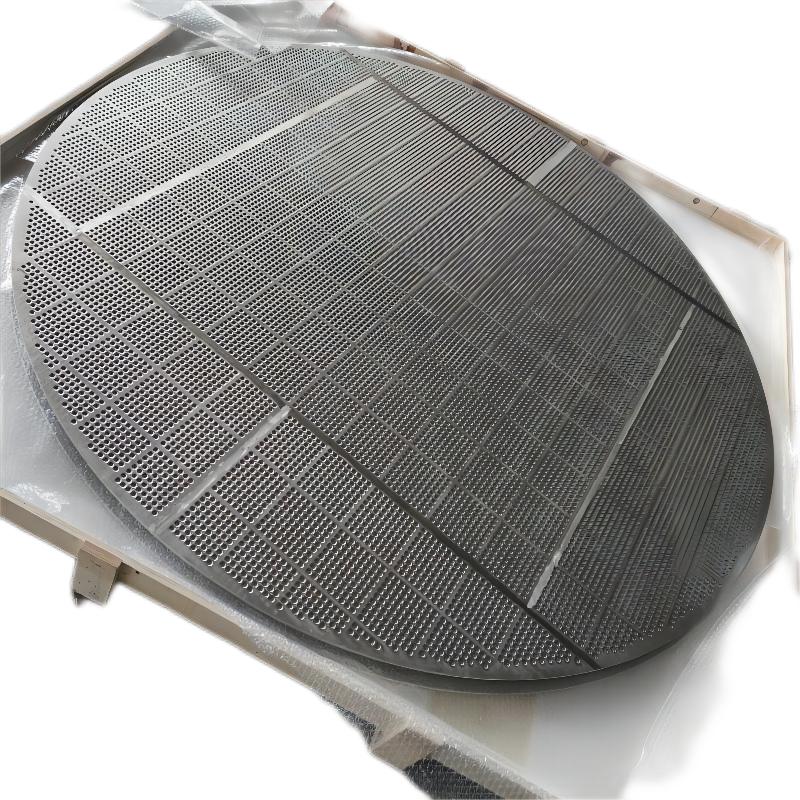

Perforated phaj sintered ntxaij yog ib hom sintered mesh uas sinters lub ntsej muag ntxig thiab lub hauv paus tiaj tus mesh ua ke. Lub plhaw phaj tau xaiv nyob rau hauv cov tuab tuab raws li cov kev xav tau, thiab lub tiaj weaving dawb tuaj yeem yog ib lossis ntau txheej. Vim yog lub punching raws li kev txhawb nqa, tus mesh compressive muaj zog thiab lub tshuab ua haujlwm muaj zog. Lub sintering ntawm ob tus tsis tsuas yog cov huab cua zoo permeability ntawm lub tiaj tiaj tus woven mesh, tab sis kuj muaj cov neeg kho tshuab lub zog ntawm lub ntxeem phaj. Nws tuaj yeem ua tiav rau hauv cylindrical, disc, ntawv thiab lub khob cooj, dav siv hauv cov dej kho, dej haus, khoom noj khoom haus, tshuaj thiab lwm yam tshuaj, thiab lwm yam.

Perforated phaj sintered mesh nta:

(1) zoo rigidity thiab muaj zog txhua yam muaj zog. Vim hais tias ntawm punching kev pab phaj phaj, nws muaj qhov siab tshaj plaws zog thiab compressive lub zog ntawm sintered meshes;

(2) Kev pom qhov tseem ceeb precision, qhov ntau ntawm kev lim pom precision yog 1μ-100, thiab nws tau txhim khu kev qha kev limtiam ua tau zoo;

(3) yooj yim los ntxuav, lub lim dej saum npoo yog saws, tshwj xeeb yog tsim rau backwashing;

(4) Nws tsis yooj yim deformed, cov duab ntawm lub ntxaij yog tsau, qhov loj ntawm qhov sib txawv yog cov khaub ncaws hnav, thiab tsis muaj qhov muag tsis pom kev.

(5) corrosion tsis kam, muaj kub ua tsis kam, tuaj yeem tiv taus qhov kub ntawm 480 ℃.

Perforated phaj sintered mesh siv:

(1) cov ntaub ntawv siv rau disporive cua txias hauv qhov chaw kub siab heev.

(2) Rau daim ntawv thov roj ua ke hauv cov hmoov txhuas kev lag luam, daim hlau ua kua dej hauv cov hlau kev lag luam.

(3) orifice phaj khoom rau roj teeb tsa lub txaj.

(4) Nws yog siv rau hauv lub moj khaum kev pom pulverized npib ntws thiab ntom theem conveying system.

(5) Pom kev, ntxuav thiab kom qhuav cov ntaub ntawv tso rau hauv kev lag luam kws tshuaj.

(6) catalyst txhawb grille.

(7) Nws yog siv rau kev lim cov polyester, roj, khoom noj thiab dej haus, tshuaj fiber ntau, thiab tseem rau cov dej kho thiab cov pa dej.