Lub tsev

Ntaub ntawv

DIN 1.4404 / AISI 316L, DIN 1.4539 / AISI 904L

Monel, Inconel, Duple Steel, Hastelloy alloys

Lwm cov ntaub ntawv muaj nyob rau ntawm kev thov.

Lim Khawm: 1 -100 microns

Cov lus qhia

| Kev Qhia Tshwj Xeeb -Thaum 6-txheej supintered mesh | ||||||||

| Kev piav txog | Lim Khawm | Lub tsev | Qhov tuab | Porosity | Huab cua permeability | Rp | Qho hnyav | Cov tawv nqaij npuas |

| μm | mm | % | (L / min / cm²) | N / cm | kg / ㎡ | (mmh₂o) | ||

| SSM-F-1 | 1 | 100 + 400x2800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 1.82 | 1080 | 8.4 | 360-600 |

| SSM-F-2 | 2 | 100 + 325x2300 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.36 | 1080 | 8.4 | 300-590 |

| SSM-F-5 | 5 | 100 + 200x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.42 | 1080 | 8.4 | 260-550 |

| SSM-F-10 | 10 | 100 + 165x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.08 | 1080 | 8.4 | 220-500 |

| SSM-F-15 | 15 | 100 + 165 x1200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.41 | 1080 | 8.4 | 200-480 |

| SSM-F-20 | 20 | 100 + 165 x800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 4.05 | 1080 | 8.4 | 170-450 |

| SSM-F-25 | 25 | 100 + 165x600 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.12 | 1080 | 8.4 | 150-410 |

| SSM-F-30 | 30 | 100 + 400 + + 100 + 64 + 64/12 | 1.7 | 37 | 6.7 | 1080 | 8.4 | 120-390 |

| SSM-F-40 | 40 | 100 + 325 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.86 | 1080 | 8.4 | 100-350 |

| SSM-F-50 | 50 | 100 + 250 + 100 + 64 + 64/12 | 1.7 | 37 | 8.41 | 1080 | 8.4 | 90-300 |

| SSM-F-75 | 75 | 100 + 200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 8.7 | 1080 | 8.4 | 80-250 |

| SSM-F-100 | 100 | 100 + 150 + 100 + 12/64 + 64/12 | 1.7 | 37 | 9.1 | 1080 | 8.4 | 70-190 |

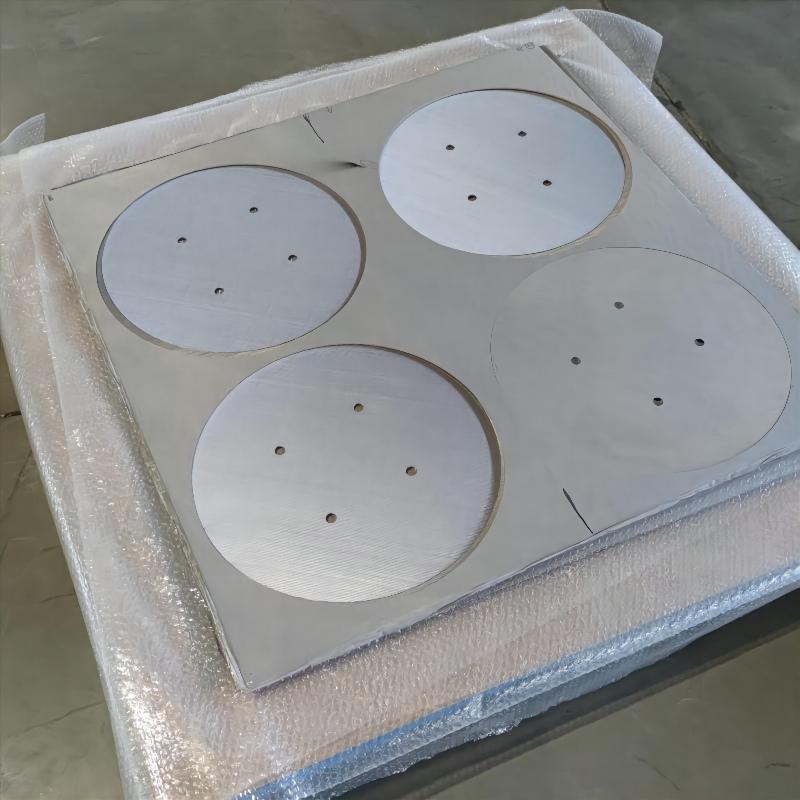

Qhov loj

Inch: 5mm-1500mm

Loj dua 1500mm, peb xav tau rau splice.

Cov Ntawv Thov

Laib cov txaj, cov txiv ntoo txiv ntoo, centrifuges, mob ntawm silos, kev siv hauv biotechnology.

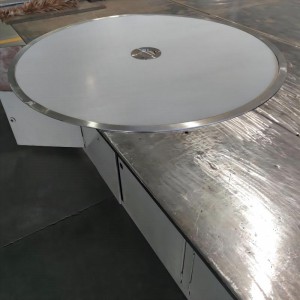

Tus txheej txheem tsib txheej txheej txheem Mesh tau muab faib ua plaub ntu: Txheej Txheem, Kev Tiv Thaiv Txheej, Dispersion Txheej thiab pob txha pob txha. Qhov no cov khoom siv lim tsis tsuas yog muaj cov khaub ncaws zoo nkauj thiab ruaj khov pom tseeb tab sis kuj muaj lub zog siab thiab ua kom nruj. Nws yog cov khoom lim dej zoo tshaj plaws rau qee lub sijhawm uas yuav tsum muaj qhov kev ua kom muaj qhov tseeb. Vim tias nws lub zog limhiam yog cov txheej txheem saum npoo, thiab tuaj yeem siv dua rau cov txheej txheem tom ntej, uas yog unmatched los ntawm txhua cov khoom siv lim. Cov khoom siv tau yooj yim rau cov qauv, cov txheej txheem thiab tuaj yeem ua tiav rau ntau hom kev lim xws li puag ncig, corratrical, conical thiab corrugated.

tus yam ntxwv

1. Lub zog siab thiab zoo rigidity: nws muaj high tshuab zog thiab compressive zog, ua haujlwm zoo, thiab siv tau yooj yim.

2. Uniform thiab ruaj khov meej: sib txawv thiab cov kev ua tau zoo thiab haum raws li tau ua rau txhua qhov kev ua kom pom tseeb, thiab cov ntxaij tsis hloov pauv thaum siv.

3. Kev siv ntau yam kev siv ib puag ncig: Nws tuaj yeem siv rau hauv qhov kub thiab txias ib puag ncig -200 ℃ ~ 600 ℃ thiab qhov pom ntawm cov kua qaub-hauv ib puag ncig.

4. Kev tu tau zoo heev: Cov txiaj ntsig zoo ntawm kev ua kom huv, tuaj yeem ntxuav kom huv, siv tau cov kev pabcuam ntev ntev (lim, melting, ci thiab lwm yam).

Lub tuam txhab muaj cov cuab yeej tsim khoom ntau dua, ib pab pawg R & D ib pab neeg, ib qho kev muag khoom lag luam zoo, thiab cov kev pabcuam muag khoom tom qab muag. Peb yuav txuas ntxiv txhim kho peb tus kheej thiab qib ntxiv, thiab txuas ntxiv kom tau raws li cov kev xav tau ntawm cov qhua tuaj noj mov nrog kev pabcuam zoo thiab txawj xav zoo.