Lub tsev

Ntaub ntawv

DIN 1.4404 / AISI 316L, DIN 1.4539 / AISI 904L

Monel, Inconel, Duple Steel, Hastelloy alloys

Lwm cov ntaub ntawv muaj nyob rau ntawm kev thov.

Lim Khawm: 1 -200 microns

Cov lus qhia

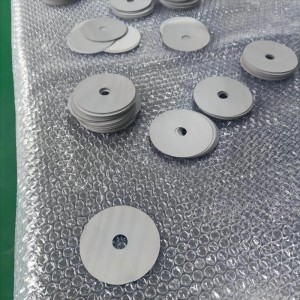

| Kev qhia tshwj xeeb - xuas nrig ntaus phaj sintered hlau mesh | ||||

| Kev piav txog | Lim Khawm | Lub tsev | Qhov tuab | Porosity |

| μm | mm | % | ||

| SSM-P-1.5T | 2-100 | 60 + filtric txheej + 60 + 30 + φ4x5px1.0t | 1.5 | 57 |

| SSM-P-2.0t | 2-100 | 30 + lim txheej + 30 + φ5x7px1.5t | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60 + filtric txheej + 60 + 30 + φ4x5px1.5t | 2.5 | 35 |

| SSM-P-3.0t | 2-200 | 60 + filtric txheej + 60 + 20 + φ6x8px2.0t | 3 | 35 |

| SSM-P-4.0t | 2-200 | 30 + lim txheej + 30 + 20 + φ8x10px2.5t | 4 | 50 |

| SSM-P-5.0t | 2-200 | 30 + lim txheej + 30 + 20 + 20 + 10 + φ8x10px3.0t | 5 | 55 |

| SSM-P-6.0t | 2-250 | 30 + lim txheej + 30 + 20 + 20 + 10 + φ8x10px4.0t | 6 | 50 |

| SSM-P-7.0t | 2-250 | 30 + lim txheej + 30 + 20 + 20 + 10 + φ8x10px5.0t | 7 | 50 |

| SSM-P-8.0t | 2-250 | 30 + lim txheej + 30 + 20 + 20 + 10 + φ8x10px6.0t | 8 | 50 |

| Lub thickness ntawm lub punching phaj thiab cov qauv ntawm cov mesh xees tuaj yeem kho tau raws li tus neeg siv yuav tsum tau ua. | ||||

Cov lus hais, yog tias nws yog siv rau hauv lub tshuab lim lim lim dej ntau heev, lub tshuab lim phaj yuav ua tau tsib txheej thiab xuas nrig ntaus phaj sintered ua ke.

Ntawd yog 100 + lim txheej + 100 + 12/64 + 64/12 + 4.0t (lossis ntawm lwm lub phaj tuab punching phaj)

Lub thickness ntawm punching phaj tseem yog nyob ntawm koj lub siab xav tau

Cov khoom no yog qhov zoo rau cov kev thov kom siab dua qub ntawm cov tshuaj thiab kev lag luam backering thiab kev lag luam online, muaj zog ntau yam.

Cov Ntawv Thov

Kev kho zaub mov & dej haus, dej kho, dej tshem tawm, chaw muag tshuaj, tshuaj lom neeg, thiab lwm yam.

Tus txheej txheem tsib-txheej supinined mesh lim cov lus yog tsuas yog dov los ntawm cov khoom siv tsib-txheej cov khoom siv lim. Tus txheej txheem tsib txheej txheej supintered hlau ntxaij yog ua los ntawm tsib txheej ntawm stainless hlau xaim mesh superimpos hlau mesh superimpos hlau mesh superimposed thiab nqus tsev sintered. Lub taub lim txheej ua los ntawm cov qauv tsib-txheej uas muaj zog, muaj zog ntxuav, thiab cov khoom siv huv thiab ntxuav cov hlau ua kom huv.

Lub puab meshes ntawm txhua txheej ntawm cov sintered ntxaij tsim qauv ua ke uas tsis tuaj yeem muab piv nrog cov khoom siv lim hlau thiab zoo tshaj plaws, ua kom nruj, thiab mesh. puab stabilityet thiab tsim tsim nyog qhov tseeb, kev ua kom zoo nkauj ntawm cov khoom, nws muaj lub zog ua haujlwm, nws muaj zog, kub ua rau, kub ua tau zoo dua. Siab dua lwm hom khoom siv lim.

1. Cov khoom nta:

1) Lub tsib-txheej subtered ntxaij yog tsim ntawm cov txheej tiv thaiv, txheej lim, txheej dispersion thiab ob txheej pob txha pob txha;

2) Lub zog siab: Tom qab sinining lub tsib-txheej xaim xees, nws muaj siab dua kev siv zog thiab compressive zog;

3) Qhov tseeb precision: nws tuaj yeem ua exert zoo li qub hais ua haujlwm rau qhov pom qhov ncauj me me ntawm 1 txog 200um;

4) Cov cua sov tiv thaiv: nws tuaj yeem siv rau kev lim dej txuas ntxiv los ntawm -200 degrees txog li 650 degrees;

5) Kev kom huv: Vim yog cov qauv lim saum npoo nrog cov txiaj ntsig zoo dua, kev tu huv si yog yooj yim.

6) Nws muaj cov pa loj loj thiab lub zog muaj zog, tsis tas yuav muaj cov ntaub ntawv uas tsis muaj kev pab cuam, tsis muaj kev tiv thaiv kev puas tsuaj, yooj yim rau kev puas tsuaj.

2.Qhov lub hom phiaj tseem ceeb:

1) siv los ua cov khoom xa tuaj txias kom txias rau hauv ib puag ncig kub siab;

2) siv rau cov roj xa tawm, orifma phaj khoom rau lub txaj tsis pub;

3) Rau siab-precision, high-cia siab rau cov khoom siv kub siab;

4) Rau siab siab Backwash Roj Lim

5) Siv rau kev lim ntawm polyester, roj ntxiv, tshuaj, khoom noj thiab dej haus, tshuaj lom neeg cov tshuaj lom neeg thiab cov pa dej.

NCO TSEG: Qhov ntev yuav ua rau raug tsim raws li cov neeg siv khoom. Tuaj yeem ua tiav rau hauv tubular, disc, tswm ciab thiab lwm yam lim.